I wanna make my own decks. I got ideas for the plate, but Im stuck with the foldy. I dont want to use razor folding mech plates cuz its complicated to get some when you dont have any. Id need help with the mech. I would like it to be independent from the neck, like the razor decks, so that it could be compatible with new parts instead of having to change the whole scoot. so how should I do my plates?

Id also like the deck to have the least welds as possible or even none at all, to make sure every deck is the same.

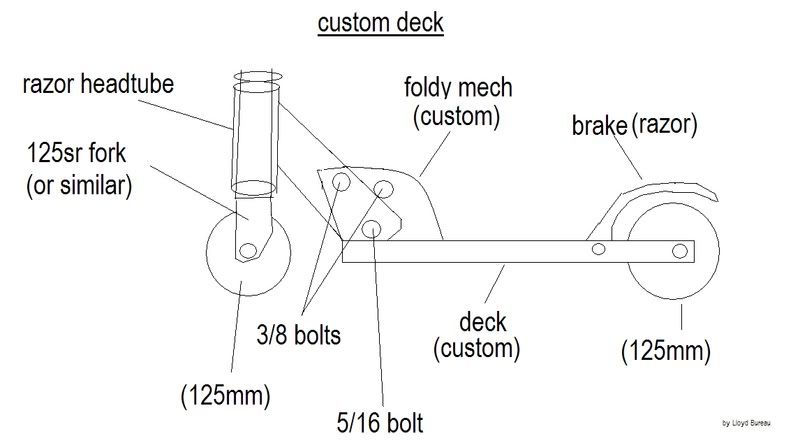

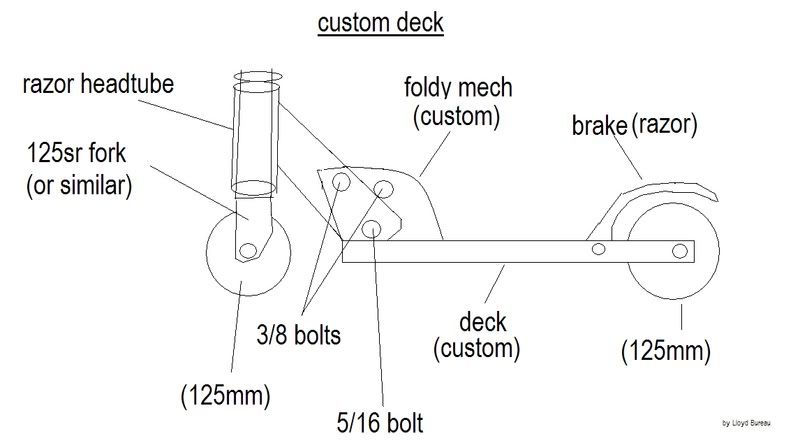

I did a little sketchup of my idea on ms paint:

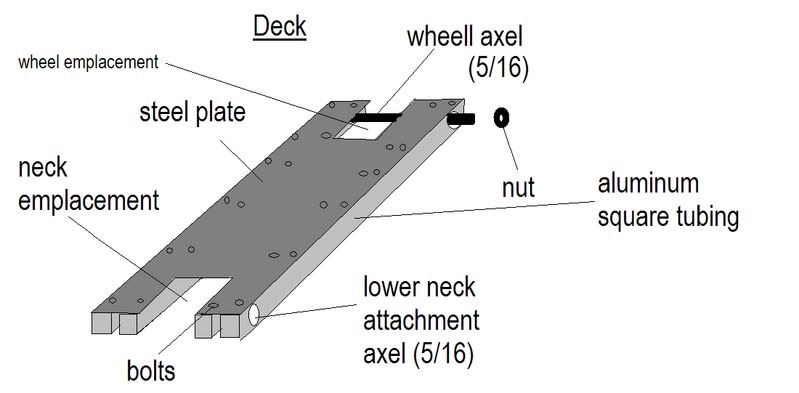

the deck Is a steel (or another solid material) plate with 4 square aluminum (or another material. I need help with the materials actually...) tubes bolted under, with the dimensions of a promodel deck. pretty simple desing actually. just need to keep the right dimensions in mind.

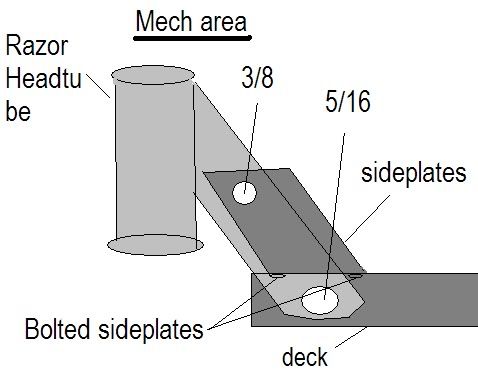

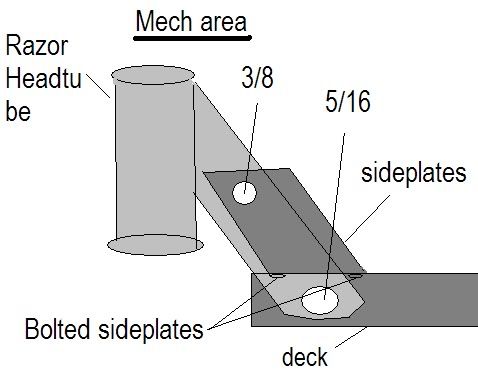

I think this could be a solid desing for the mech area. my idea is to avoid as most as possible welding jobs. only bolts:

additionnal holes on the plates could be made to adjust the angle (for people who like 90 degree style angles or others who want smaller angles)

welding on the plates will also be added now with the feedback I have received.

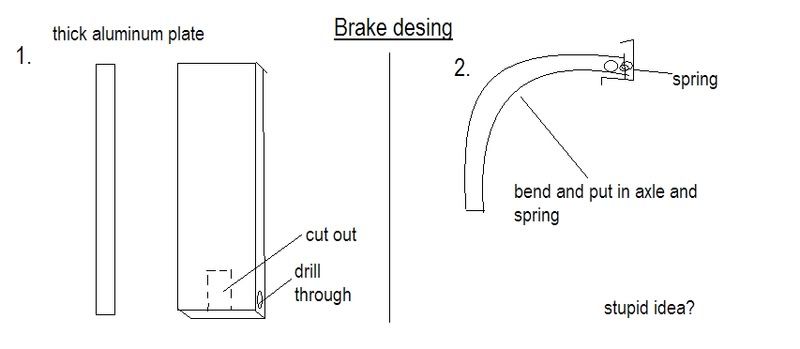

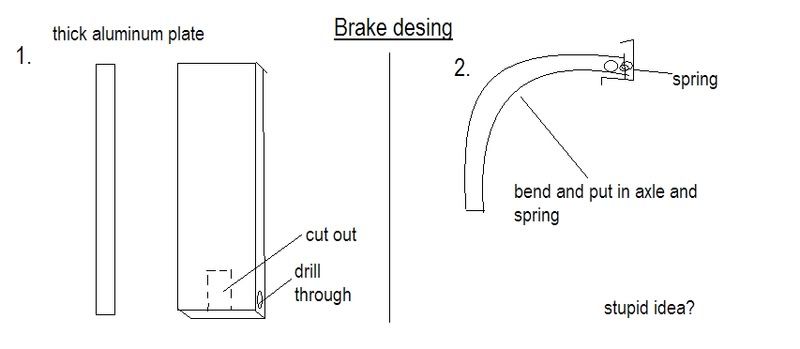

brake desing (prolly not happening):

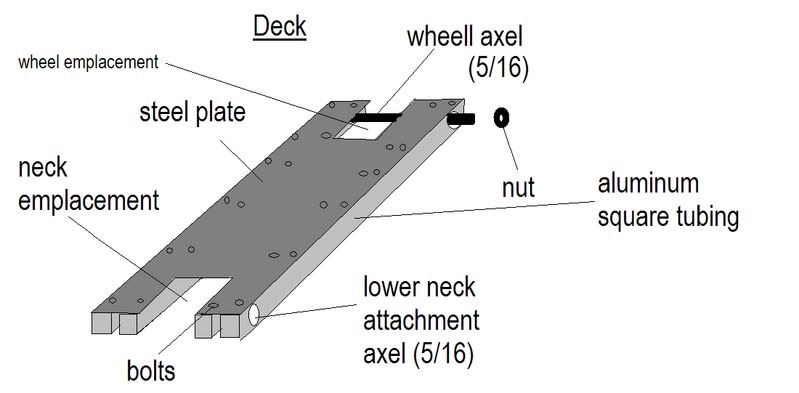

heres what the deck will look like without the foldy plates and the brake:

I am now making the plans and Im going to buy the materials in a week or so.

thank you for your help

Id also like the deck to have the least welds as possible or even none at all, to make sure every deck is the same.

I did a little sketchup of my idea on ms paint:

the deck Is a steel (or another solid material) plate with 4 square aluminum (or another material. I need help with the materials actually...) tubes bolted under, with the dimensions of a promodel deck. pretty simple desing actually. just need to keep the right dimensions in mind.

I think this could be a solid desing for the mech area. my idea is to avoid as most as possible welding jobs. only bolts:

additionnal holes on the plates could be made to adjust the angle (for people who like 90 degree style angles or others who want smaller angles)

welding on the plates will also be added now with the feedback I have received.

brake desing (prolly not happening):

heres what the deck will look like without the foldy plates and the brake:

I am now making the plans and Im going to buy the materials in a week or so.

thank you for your help