jimvandeveld

Bronze member

those actually seem like a really good design. just one question. how are you keeping the 2 pieces from spinning on each other or coming apart from each other? a slit or something? and also just a little constructive criticism, get some better welds, and they will be so legit

My name is Jim Vandeveld, and I'm a toolmaker in Erie, PA as well as the co-founder of Cycle Mayhem.

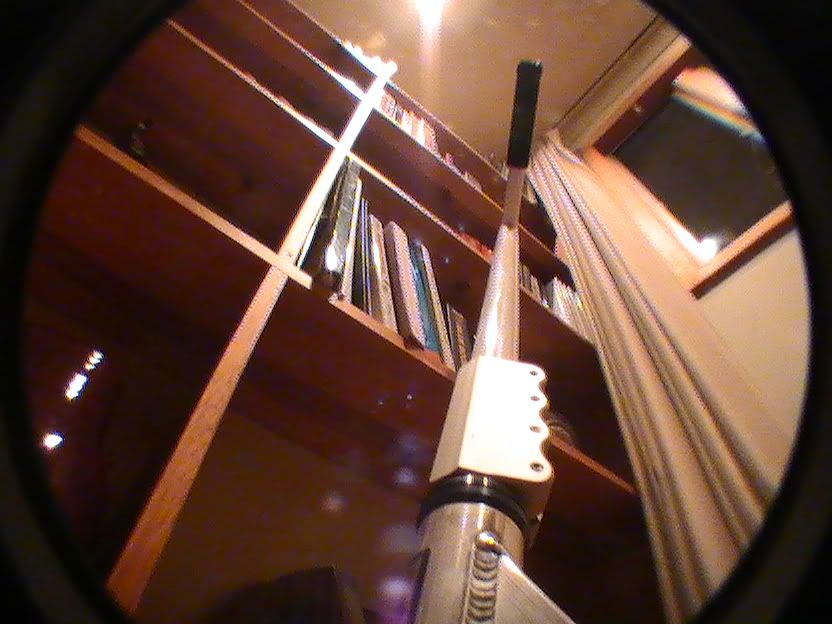

Thanks for taking the time to answer intelligently bro- and as for the rest of the negative criticism- justifiable, but to be honest, a little rude. That is fine though, you all are completely entitled to your own opinions. In response to your question Michael, in the pictures it is unseen but on the back of the bars the top piece is notched and the downtube has an insert that was attached to it, which lock together and prevent the bars from spinning. The downtube has nut welded to the top of it, and we used a large bolt as well to ensure that it could be locked down thoroughly. These welds were a bit rough, but the bottom line is that what you see here is the very first prototype, which squeak has been riding for some time now, and the welds have held up just fine. I understand that they arent a picture perfect bead, but they are strong. I'm not here to convince you to change your mind, but the idea behind Cycle Mayhem was to bring new and innovative ideas to our sport, and I feel like this is an example of what we're trying to do. We're not trying to make it big, we're just a couple guys who like all things two wheeled and thought we had a few cool ideas floating around and decided to make them into a reality. And so far in our opinion they've worked out well. So, although some of your feelings were positive, I'm not here to criticize you in return, and in fact your feedback will be duely noted. Hopefully the next set of pictures will better portray the quality of our work, and i apologize if these welds turned some of your stomachs, but once again I assure you they are much stronger than some of you are saying. Thank you to those of you for your support that provided it! And thanks to hep greg for noticing what a treasure those old ass demo grips really are.